Delivery Time: 15-21 days

Service: OEM & ODM

Certification: CE, ROHS, ISO9001

Place Of Origin: Guangdong, China

FOB Port: Foshan, Guangzhou, Shenzhen

Payment Term: T/T, L/C or other payment term can be negociated.

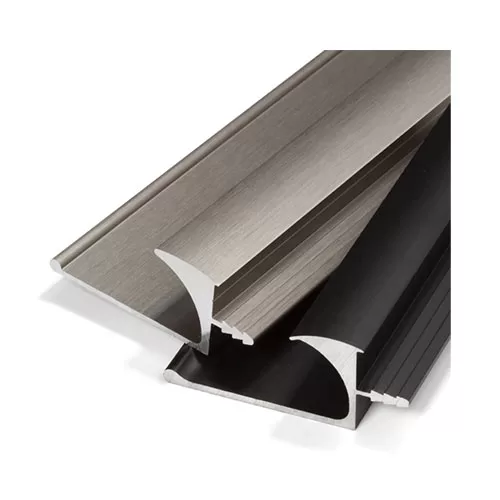

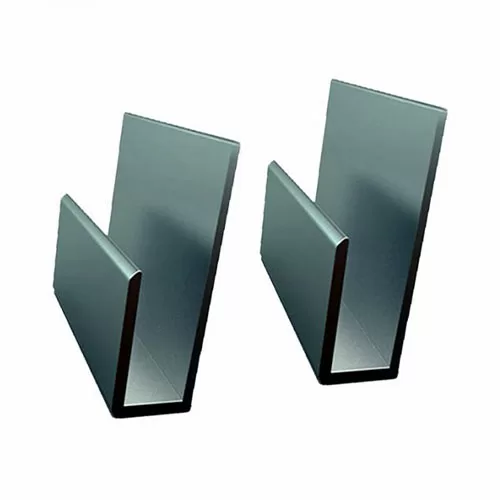

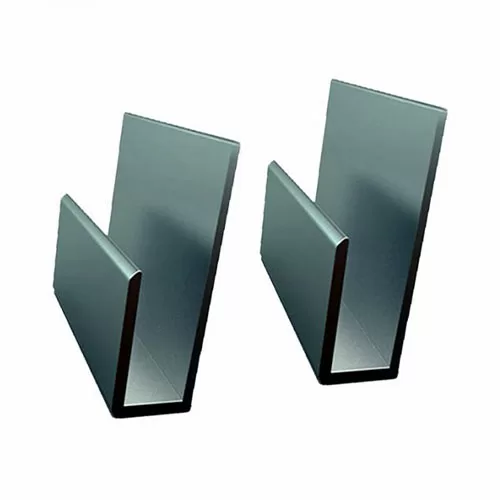

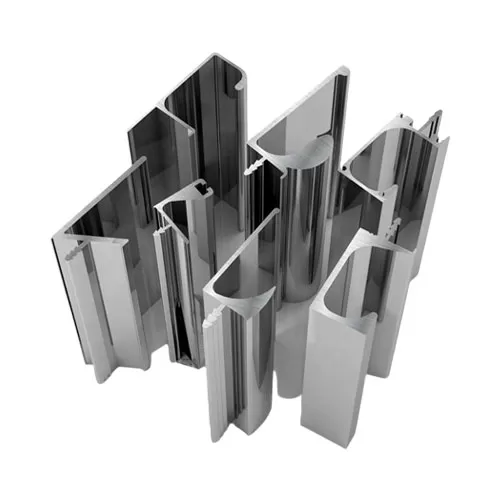

The Aluminum J channel profile is a versatile and essential component used in various construction and design applications. Its unique “J” shape allows for easy installation and provides a sleek and finished look to a wide range of projects.

One of the primary uses of the Aluminum J channel profile is in siding installation. It serves as a receiver for the edges of siding panels, creating a neat and uniform appearance while also protecting the edges from moisture and other environmental elements. The channel profile helps to channel water away from the building, preventing water damage and ensuring the longevity of the siding.

Additionally, the Aluminum J channel profile is widely utilized in the installation of soffits and fascia boards. It provides a secure mounting surface for these components and helps to conceal the edges of roofing materials, giving the roofline a clean and polished look. The profile also aids in ventilation, allowing air to flow freely through the attic space and preventing moisture buildup.

In interior design, the Aluminum J channel profile finds application in various finishing projects. It can be used to trim the edges of countertops, shelves, and cabinetry, providing a professional and refined appearance. The profile is also employed in drywall installation, where it acts as a support for gypsum panels and helps to create seamless transitions between different wall surfaces.

Overall, the Aluminum J channel profile is valued for its versatility, durability, and ease of installation. Whether used in exterior siding projects or interior finishing work, it contributes to the aesthetic appeal and functionality of a wide range of architectural designs.

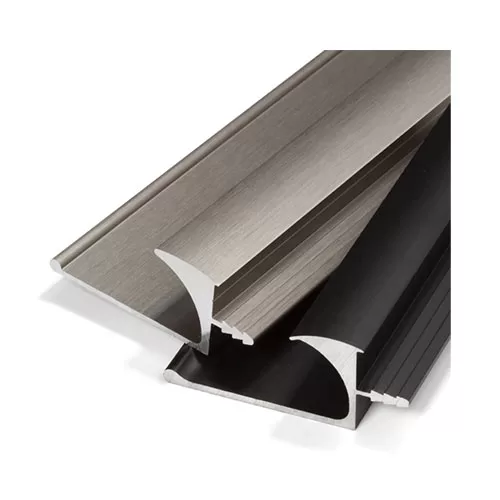

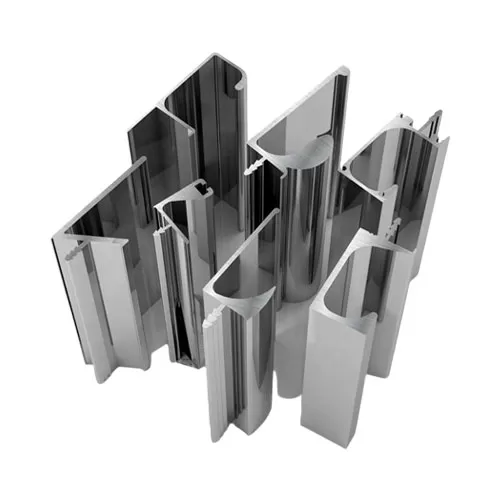

The Aluminum J channel profile finds practical applications in residential interior and exterior design projects due to its versatility and functionality. In home construction and renovation, it serves several purposes:

Siding Installation: One of the primary uses of the Aluminum J channel profile in home exteriors is as a receiver for siding panels. It provides a clean and finished look to the edges of the siding while also acting as a protective barrier against moisture infiltration.

Soffit and Fascia: The profile is commonly employed in soffit and fascia installations. It helps to create a neat transition between the exterior wall and the roofline, providing structural support and enhancing the overall appearance of the home.

Interior Trim: Inside the home, the Aluminum J channel profile can be utilized as trim around doors, windows, and baseboards. Its sleek design adds a modern touch to interior spaces while concealing rough edges and creating a seamless transition between different surfaces.

Cabinet and Shelving: In kitchen and bathroom renovations, the profile can be repurposed as a mounting bracket for cabinets, shelves, or backsplashes. Its sturdy construction and easy installation make it a practical choice for securing these fixtures to the wall.

Decorative Accents: Additionally, the Aluminum J channel profile can be used creatively as a decorative accent in various areas of the home. It can frame mirrors, highlight architectural features, or even serve as a rail for hanging artwork or curtains.

Overall, the Aluminum J channel profile’s adaptability and aesthetic appeal make it a versatile solution for enhancing both the exterior and interior aesthetics of residential properties.

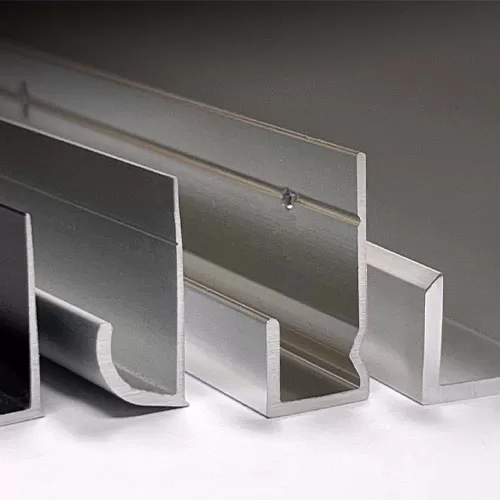

| Extrusion Line: | 12 extrusion lines and monthly output can reach 5000 tons. | |

| Production Line: | 5 production line for CNC | |

| Product Capacity: | Anodizing Electrophoresis monthly output is 2000 tons. | |

| Powder Coating monthly output is 2000 tons. | ||

| Wood Grain monthly output is 1000 tons. | ||

| Alloy: | 6063/6061/6005/6060/7005. (Special alloy could be made upon your requirements.) | |

| Temper : | T3-T8 | |

| Standard: | China GB high precision standard. | |

| Thickness: | Based on your requirements. | |

| Length: | 3-6 M or customized length. And we can produce any length you want. | |

| MOQ: | Normally 2 tons. Usually 15-17 tons for 1*20GP and 23-27 tons for 1*40HQ. | |

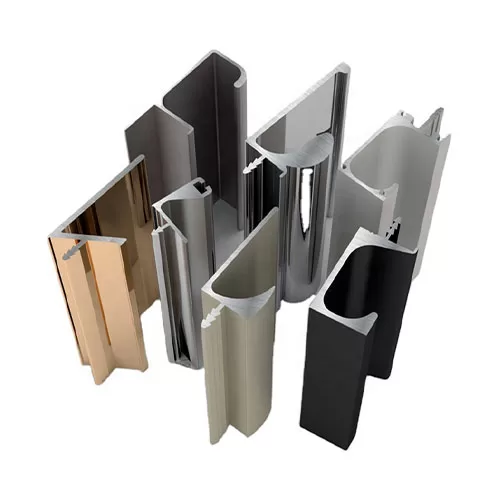

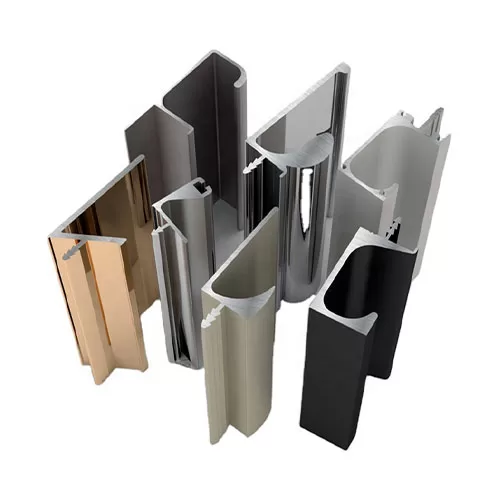

| Surface Finish: | Mill finish, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. | |

| Color We Can Do: | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. | |

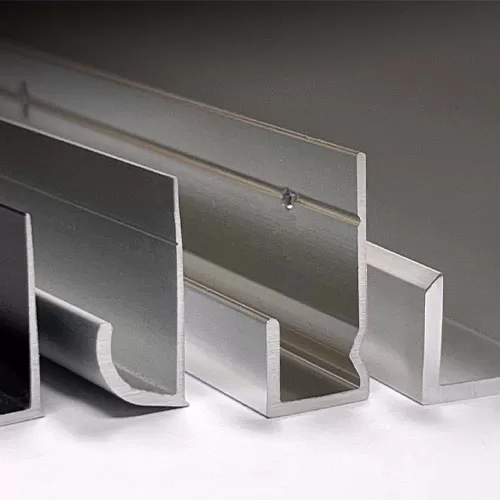

| Film Thickness: | Anodized: | Customized. Normal thickness: 8 um-25um. |

| Powder Coating: | Customized. Normal thickness: 60-120 um. | |

| Electrophoresis Complex Film: | Normal thickness: 16 um. | |

| Wood Grain: | Customized. Normal thickness: 60-120 um. | |

| Wood Grain Material: | a). Imported Italian MENPHIS transfer printing paper.

b). High quality China transfer printing paper brand. c). Different prices. |

|

| Chemical Composition & Performance: | Meet and execution by the China GB high precision level. | |

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | |

| Packing: | Plastic film & Kraft paper. Protect film for each piece of profile is also ok if required. | |

| FOB Port: | Foshan,Guangzhou,Shenzhen. | |

| OEM: | Available. | |