Foshan Xingtao aluminum co., ltd., established in 1992, covers an area of over 30000 square meters, with total investment exceeding rm200 million. The company has strong technical force, with over 300 employees, including over 20 modern management people and over 10 senior technicians. The company has aluminum profiles production lines that are advanced in the country, extruding, anodizing, electro-coating, power coating, mold, wood grain and such large workshops, and with advanced testing instrument of various kinds.

And perfect testing measures. Computerized management is adopted in production and sales, and advanced management modes of large overseas aluminum profiles enterprises are introduced in. The company relies on senior talents, advanced facilities and testing instrument, perfect and efficient management system for stringent control over each every stage from raw materials entering the company to finished products leaving the company, for constant improvement of product quality. Main products of the company include aluminum alloy architectural profiles and industrial profiles, with annual production capacity exceeding 60000 tons.

Our products are sold throughout the country. And are exported to over 20 countries and regions like australia, canada. Usa, japan, singapore, thailand, malaysia, russia, africa, hong kong, macau, taiwan and so on. The company has independent rights of export, and has perfect marketing systems and senior marking people. Resulting in constant improvement of product popularity, increase of market coverage and stable increase of sales.

Actively, rapidly and efficiently solving any problems which the customer mentioned enables the customer to feel the greatest satisfaction.

The XT design team currently has a total of 35 people which is divided into a die design department and product design department. After years of cooperation, the workshop between them is very tacit.

XT Company owns a complete line of mechanical equipment needed for the production of aluminum profiles and are experts in the auxiliary processes and technological processes.

Xingtao aluminum attaches great importance to the quality of our aluminum products. In order to ensure the quality, we have a professional testing team.

Aluminum Factory Prototype Design: Innovating the Future of Manufacturing

The design of a prototype for an aluminum factory is a crucial step in the process of creating a state-of-the-art manufacturing facility. Aluminum, known for its lightweight and durable properties, is a widely used material in various industries, including automotive, aerospace, and construction. Therefore, the design of a prototype for an aluminum factory must incorporate the latest technological advancements and innovative practices to ensure efficiency, sustainability, and high-quality production.

One of the key aspects of the prototype design is the integration of advanced automation and robotics. By implementing automated systems in the production process, the factory can significantly increase productivity, reduce operational costs, and enhance safety for workers. Robotics can handle repetitive tasks with precision and speed, leading to a more streamlined and efficient manufacturing process.

Furthermore, the prototype design should prioritize sustainability and environmental responsibility. Implementing eco-friendly practices, such as energy-efficient machinery and waste reduction measures, can minimize the environmental impact of the factory’s operations. Additionally, utilizing recycled aluminum and implementing sustainable production methods can contribute to a more sustainable and circular economy.

In addition to automation and sustainability, the prototype design should also focus on flexibility and adaptability. The ability to quickly reconfigure production lines and adapt to changing market demands is essential for a modern manufacturing facility. By incorporating modular design principles and flexible manufacturing systems, the factory can easily adjust its production processes to accommodate new product designs and variations.

Moreover, the use of advanced data analytics and digital technologies can optimize the production process and improve overall efficiency. By leveraging real-time data and predictive analytics, the factory can make informed decisions, identify potential bottlenecks, and continuously improve its operations.

In conclusion, the design of a prototype for an aluminum factory represents a significant opportunity to innovate the future of manufacturing. By integrating advanced automation, sustainability practices, flexibility, and digital technologies, the prototype can serve as a blueprint for a cutting-edge aluminum production facility. Ultimately, this forward-thinking approach can lead to a more efficient, sustainable, and competitive manufacturing industry.

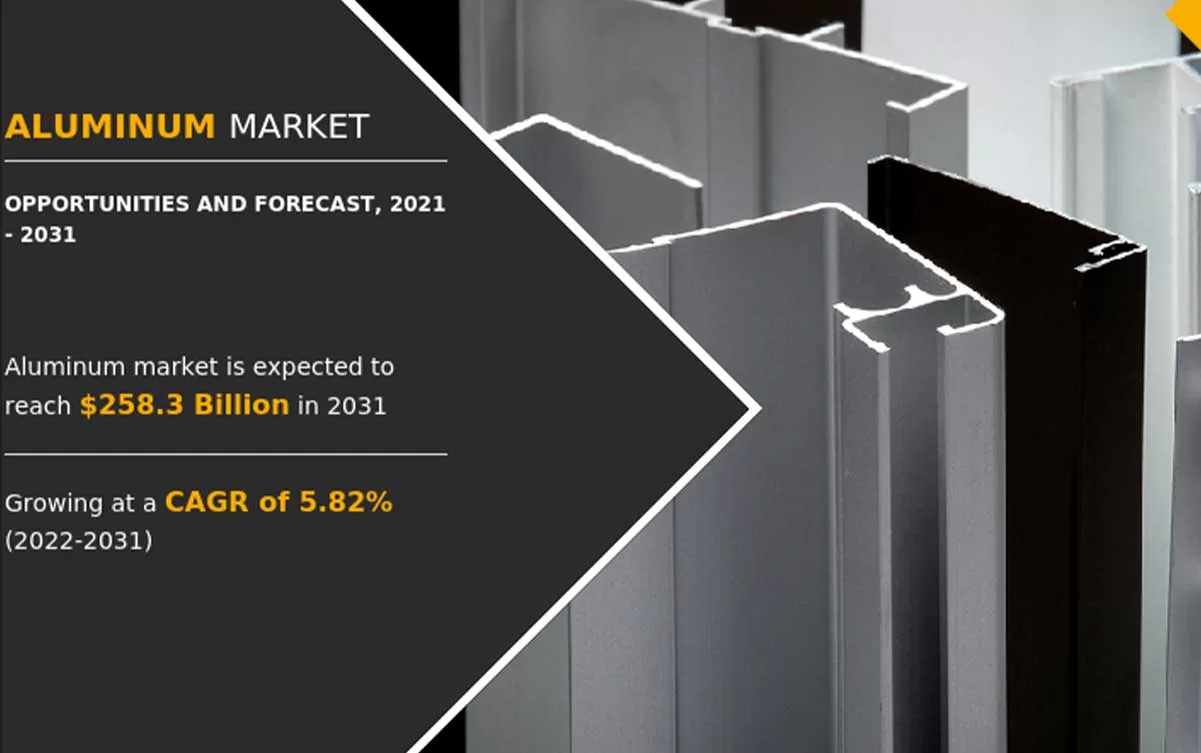

Aluminum Product Demand Analysis: Understanding Market Trends and Opportunities

The demand for aluminum products has been steadily increasing in recent years, driven by a variety of factors such as the growing automotive and aerospace industries, the rise in construction activities, and the increasing use of aluminum in consumer electronics and packaging. As a result, conducting a comprehensive demand analysis for aluminum products is crucial for businesses operating in this sector.

One of the key drivers of the increasing demand for aluminum products is the automotive industry. With the push towards lightweight and fuel-efficient vehicles, automakers are increasingly turning to aluminum to reduce the weight of their vehicles and improve fuel efficiency. This trend is expected to continue, especially with the growing popularity of electric vehicles, where the lightweight properties of aluminum are particularly advantageous.

In addition to the automotive industry, the aerospace sector is also a significant contributor to the demand for aluminum products. The use of aluminum in aircraft manufacturing is well-established, and with the increasing global air traffic, the demand for new aircraft is expected to remain strong, further driving the demand for aluminum products.

Furthermore, the construction industry is another major consumer of aluminum products. The metal’s corrosion resistance, strength, and versatility make it a popular choice for a wide range of construction applications, including windows, doors, roofing, and structural components.

Consumer electronics and packaging are also driving the demand for aluminum products. The metal’s lightweight and recyclable properties make it an attractive choice for manufacturers of electronic devices and packaging materials, especially as sustainability and environmental concerns continue to influence consumer preferences.

Conducting a thorough demand analysis for aluminum products involves examining market trends, understanding the needs and preferences of end-users, and identifying potential growth opportunities. By gaining insights into the factors driving demand, businesses can make informed decisions regarding production, pricing, and market positioning to capitalize on the growing demand for aluminum products.

In conclusion, the demand for aluminum products is being fueled by diverse industries, presenting significant opportunities for businesses operating in this sector. By conducting a comprehensive demand analysis, companies can gain a deeper understanding of market trends and consumer preferences, enabling them to strategically position themselves to meet the growing demand for aluminum products.

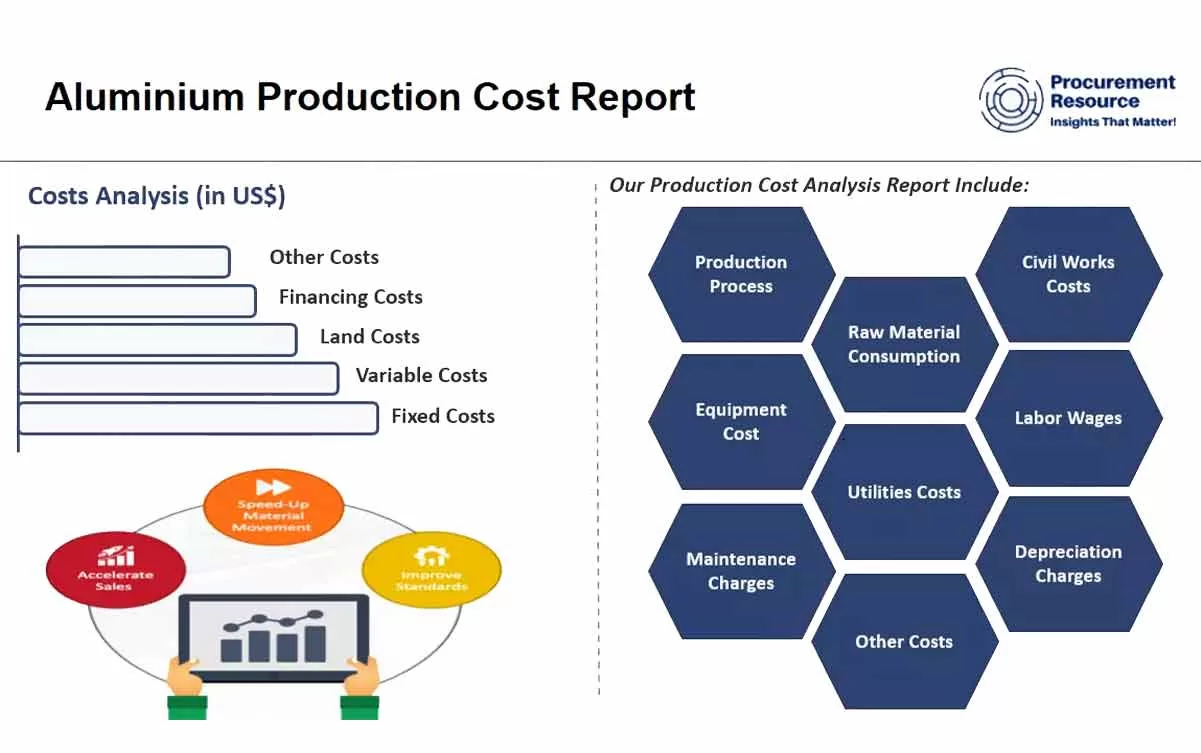

Cost evaluation in an aluminum factory involves assessing and managing various expenses incurred throughout the manufacturing process. Here’s a breakdown of the key cost considerations:

Raw Materials: The cost of raw materials, primarily aluminum ingots or scrap, is a significant factor. Prices can fluctuate based on market demand, supply, and material quality. Evaluating suppliers and negotiating favorable contracts can help manage this cost.

Energy Consumption: Aluminum production is energy-intensive, particularly during the smelting process. Monitoring and optimizing energy usage through efficient technologies and processes can help reduce costs.

Labor Costs: Labor costs include wages, benefits, and training expenses for factory workers involved in production, quality control, maintenance, and administration. Balancing workforce efficiency and productivity with labor expenses is crucial.

Equipment and Machinery: Investment in machinery, furnaces, casting equipment, and other infrastructure is necessary for aluminum manufacturing. Capital expenses, maintenance, repairs, and upgrades contribute to the overall cost.

Overheads: Overhead expenses encompass indirect costs such as facility rent or mortgage, utilities, insurance, taxes, and administrative expenses. Managing overheads efficiently is essential for controlling overall costs.

Transportation and Logistics: Shipping raw materials to the factory and distributing finished products to customers incur transportation costs. Optimizing logistics, choosing cost-effective transportation methods, and negotiating favorable contracts with carriers can minimize expenses.

Waste Management and Environmental Compliance: Proper waste management, recycling, and compliance with environmental regulations add to operational costs. Implementing sustainable practices can mitigate environmental impact while managing expenses.

Quality Control and Assurance: Quality control measures, including inspections, testing, and certification, ensure that products meet required standards. While these activities add to production costs, they help prevent defects and ensure customer satisfaction.

Research and Development: Investment in research and development (R&D) for product innovation, process improvement, and technology advancement is essential for staying competitive. R&D expenses contribute to long-term growth and profitability.

Market Dynamics: Economic factors, market demand, competition, and pricing strategies influence revenue generation and profitability. Monitoring market trends and adjusting production levels and pricing accordingly is essential for financial viability.

Risk Management: Identifying and mitigating risks such as supply chain disruptions, price volatility, regulatory changes, and market fluctuations is crucial for minimizing financial losses and maintaining stability.

Capital Investment and Financing: Funding capital projects, expansions, or upgrades may require financing through loans, equity investments, or other sources. Evaluating the cost of capital and managing debt effectively is essential for financial health.

By carefully analyzing and managing these cost factors, aluminum factories can optimize operations, improve profitability, and maintain competitiveness in the industry. Regular review and adjustment of cost-saving strategies are necessary to adapt to changing market conditions and achieve sustainable growth.

Introduction to Aluminum Mold Manufacturing

Aluminum mold manufacturing stands at the forefront of modern industrial production, offering unparalleled versatility, efficiency, and cost-effectiveness. With applications spanning from automotive to consumer electronics, aluminum molds have become indispensable in shaping the products we use daily.

Advantages of Aluminum Molds:

Lightweight: Aluminum molds are easier to handle and install, reducing operational strain and setup time.

Enhanced Thermal Conductivity: Superior thermal conductivity enables rapid cooling, resulting in shorter production cycles and increased output.

Cost-Effectiveness: Despite initial investment, aluminum molds offer long-term savings through durability, reduced maintenance, and faster production.

Precision Engineering: Aluminum’s machinability allows for intricate mold designs and precise part replication, meeting the highest quality standards.

Corrosion Resistance: Natural resistance to corrosion ensures prolonged mold life, even in challenging operating environments.

Manufacturing Process:

Aluminum mold fabrication typically involves advanced techniques such as CNC machining, EDM (Electrical Discharge Machining), and surface treatments like anodizing or coating for added durability and surface finish.

Applications:

From automotive components to consumer electronics and beyond, aluminum molds cater to diverse industries seeking high-quality, cost-efficient production solutions.

Future Directions:

Ongoing research focuses on refining aluminum alloys, optimizing manufacturing processes, and incorporating digital technologies like AI and additive manufacturing to further enhance mold performance and efficiency.

Conclusion:

Innovation in aluminum mold manufacturing continues to drive industrial progress, offering unmatched versatility, precision, and cost-effectiveness in producing a wide array of products. As industries evolve, aluminum molds stand ready to meet the challenges of tomorrow’s manufacturing landscape.

Quality control in an aluminum factory is crucial for ensuring that the produced aluminum meets required standards and specifications. Here’s an overview of the quality control process in such a facility:

Raw Material Inspection: Quality control starts with the inspection of raw materials. Raw aluminum ingots or scrap materials need to be checked for purity, composition, and any impurities that could affect the final product.

Melting and Alloying: During the melting process, quality control measures ensure that the correct temperature is maintained, and the alloying elements are added in the right proportions to achieve the desired alloy composition.

Casting or Forming: Whether the aluminum is cast into ingots, rolled into sheets, extruded into shapes, or processed in any other way, quality control checks ensure that the dimensions, surface finish, and structural integrity meet the required standards.

Heat Treatment: Some aluminum alloys require heat treatment to achieve the desired mechanical properties. Quality control ensures that the heat treatment process is carried out accurately, with precise temperature control and duration.

Surface Treatment: Surface treatments like anodizing, painting, or coating are often applied to aluminum products for corrosion resistance or aesthetic purposes. Quality control checks ensure that these treatments are applied uniformly and adhere properly to the surface.

Mechanical Testing: Various mechanical tests are conducted on samples of the finished aluminum products to assess properties such as tensile strength, hardness, ductility, and impact resistance. These tests help verify that the material meets the required mechanical specifications.

Chemical Analysis: Periodic chemical analysis of the finished aluminum products is performed to verify the alloy composition and identify any impurities that could affect performance or quality.

Dimensional Inspection: Dimensional accuracy is crucial, especially for aluminum parts used in precision engineering or manufacturing. Quality control involves measuring and inspecting dimensions using calibrated instruments to ensure compliance with specifications.

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiography, or eddy current testing may be employed to detect internal defects or flaws in aluminum products without causing damage.

Traceability and Documentation: Throughout the manufacturing process, quality control records are maintained to track the production history of each batch of aluminum products. This traceability ensures accountability and facilitates the identification of any issues that arise.

Continuous Improvement: Quality control is not a one-time activity but an ongoing process. Feedback from inspections, tests, and customer feedback is used to identify areas for improvement in the manufacturing process and product quality.

By implementing comprehensive quality control measures at every stage of the manufacturing process, aluminum factories can produce high-quality products that meet the needs and expectations of their customers.

For information regarding the delivery of an order from an aluminum factory, you’ll typically need to contact the factory directly or the entity through which you placed the order. They should be able to provide you with details on the status of your order, estimated delivery times, tracking information (if available), and any other relevant information.

If you have a reference number or order confirmation email, that would be useful to have on hand when reaching out to them. They can usually provide you with the most accurate and up-to-date information regarding your order’s delivery.

Aluminum Factory Order Delivery: Ensuring Timely and Efficient Service

In the fast-paced world of manufacturing, the timely delivery of orders is crucial for maintaining customer satisfaction and meeting production deadlines. This is especially true for aluminum factories, where the demand for high-quality aluminum products is constantly on the rise. To ensure that orders are delivered promptly and efficiently, aluminum factories employ a range of strategies and processes to streamline their delivery operations.

One of the key factors in ensuring timely order delivery is effective communication and coordination between the various departments within the aluminum factory. From the moment an order is placed, it is essential for the sales, production, and logistics teams to work together seamlessly to ensure that the order is processed, manufactured, and dispatched without any delays. This requires clear communication channels, efficient order tracking systems, and a proactive approach to addressing any potential issues that may arise during the production and delivery process.

Another important aspect of efficient order delivery is the use of advanced technology and automation in the production and logistics processes. Many aluminum factories have invested in state-of-the-art manufacturing equipment and automated systems to optimize production efficiency and minimize lead times. Additionally, the use of advanced logistics software and tracking systems enables real-time monitoring of order status and delivery progress, allowing for proactive intervention in case of any potential delays.

Furthermore, the strategic location of the aluminum factory’s distribution centers and warehouses plays a crucial role in ensuring timely order delivery. By strategically positioning these facilities in close proximity to major transportation hubs and customer locations, the factory can minimize transit times and expedite the delivery process. This not only reduces the risk of delays but also helps in optimizing the overall logistics and supply chain management.

In addition to these internal strategies, aluminum factories also work closely with reliable transportation and shipping partners to ensure the smooth and timely delivery of orders. By partnering with reputable carriers and logistics providers, the factory can leverage their expertise and resources to expedite the transportation of orders to their final destinations.

In conclusion, the timely delivery of orders is a top priority for aluminum factories, and they employ a range of strategies to ensure efficient and reliable service. By focusing on effective communication, advanced technology, strategic location, and strong partnerships, aluminum factories can meet the demands of their customers and maintain a competitive edge in the industry.

Aluminum Factory Mass Production: Meeting the Growing Demand

In today’s industrial landscape, the demand for aluminum products continues to rise, driving the need for efficient mass production in aluminum factories. The versatility, durability, and lightweight nature of aluminum make it a popular choice across various industries, from automotive and aerospace to construction and packaging. As a result, aluminum factories are constantly striving to optimize their production processes to meet the increasing demand for aluminum products.

Mass production in aluminum factories involves the use of advanced technologies and streamlined manufacturing processes to produce large quantities of aluminum products efficiently. One of the key factors in achieving mass production is the utilization of automated systems and robotics, which can perform repetitive tasks with precision and speed. This not only increases the output but also ensures consistent quality across the products.

Furthermore, the implementation of lean manufacturing principles has revolutionized the mass production of aluminum products. By minimizing waste, optimizing workflow, and improving overall efficiency, aluminum factories can significantly increase their production capacity while reducing costs. This approach allows for the seamless integration of various production stages, from casting and extrusion to machining and finishing, resulting in a continuous and efficient manufacturing process.

The use of advanced casting and molding techniques also plays a crucial role in aluminum mass production. High-pressure die casting and permanent mold casting are commonly employed to create complex aluminum components with high dimensional accuracy. These methods enable the production of a wide range of aluminum parts and components, catering to diverse industry requirements.

In addition to technological advancements, the sustainability aspect of aluminum mass production cannot be overlooked. Many aluminum factories are adopting eco-friendly practices, such as recycling scrap aluminum and optimizing energy consumption, to minimize their environmental impact while meeting the growing demand for aluminum products.

As the demand for aluminum products continues to soar, aluminum factories are embracing innovation and efficiency to ensure that mass production capabilities keep pace with market needs. By leveraging advanced technologies, optimizing manufacturing processes, and prioritizing sustainability, these factories are poised to meet the challenges of mass production while delivering high-quality aluminum products to a diverse range of industries.

In 1992, Foshan Xingtao Aluminum Company was established in Nanhai Dali.

Foshan Xingtao aluminum company expanded its production scale, with a factory area of 50000 square meters.

Foshan Xingtao aluminum company increased investment in production equipment and added 8 extrusion production lines within the year.

Foshan Xingtao aluminum has an annual production capacity of 50000 ton and has cooperated with many well-known domestic enterprises.

Foshan Xingtao aluminum was recognized as a well-known trademark in China.

Foshan Xingtao aluminum set up a customized service center for aluminum products, providing one-stop services of design, processing and surface treatment.

Foshan Xingtao aluminum did not stop in the face of the new Crown epidemic, they still kept moving forward and their performance rose steadily.

PRODUCTS

Foshan Xingtao Aluminum Co., Ltd.

Sara

Ace

+86-18022791554

+86-18022395098

CONTACT