Delivery Time: 15-21 days

Service: OEM & ODM

Certification: CE, ROHS, ISO9001

Place Of Origin: Guangdong, China

FOB Port: Foshan, Guangzhou, Shenzhen

Payment Term: T/T, L/C or other payment term can be negociated.

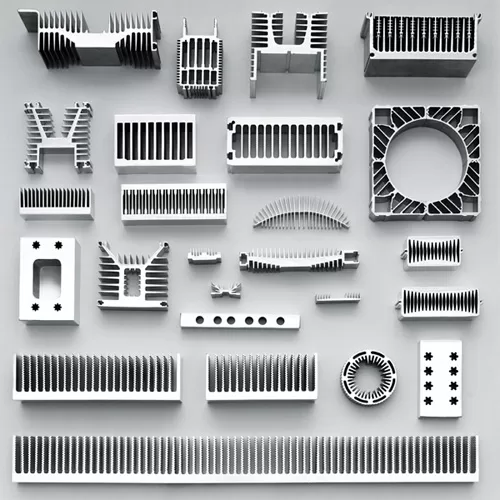

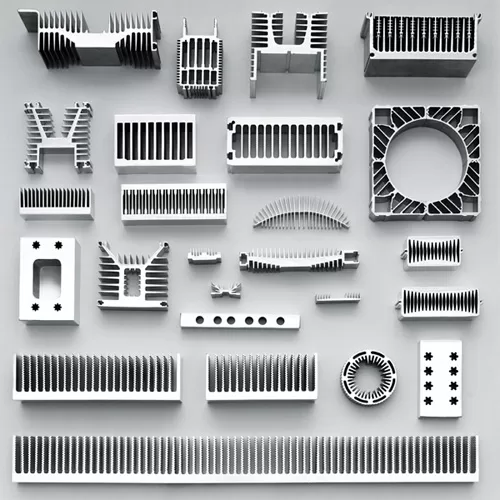

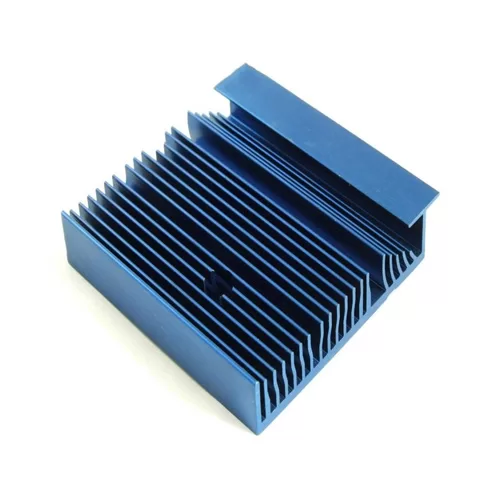

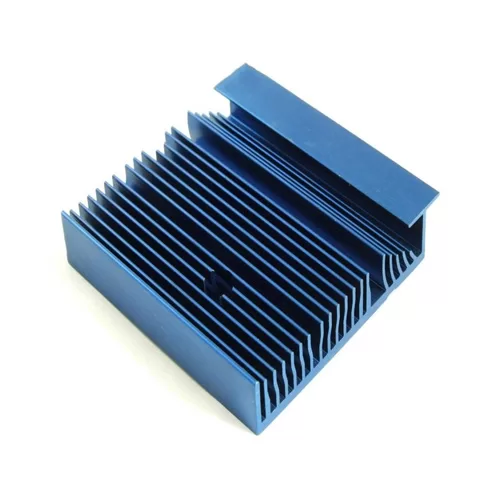

Aluminum heat sink profiles are essential components in various industries, providing efficient thermal management solutions for electronic devices, LED lighting systems, automotive components, and more. These profiles are specifically designed to dissipate heat generated by electronic components, ensuring optimal performance and reliability. Here’s why aluminum heat sink profiles are preferred in thermal management applications.

Aluminum heat sink profiles are essential components used in various industries due to their excellent thermal conductivity, lightweight design, and versatility. They find widespread application in electronics, LED lighting systems, automotive, industrial machinery, and renewable energy systems.

In the electronics industry, aluminum heat sink profiles are crucial for dissipating heat generated by components like CPUs, GPUs, and power transistors in computers, smartphones, and other devices.

LED lighting systems benefit from aluminum heat sink profiles to efficiently dissipate heat from LED modules, ensuring consistent light output and extended lifespan of bulbs and fixtures.

In the automotive sector, these profiles help cool down electronic components such as engine control units, LED headlights, and EV batteries, contributing to vehicle safety and reliability.

Industrial machinery relies on aluminum heat sink profiles to manage heat from motors, power supplies, and control systems, ensuring optimal performance and minimizing downtime.

Moreover, in renewable energy systems like solar inverters and wind turbines, these profiles play a vital role in managing heat generated by power electronics, enhancing system efficiency and reliability.

In summary, aluminum heat sink profiles are indispensable in modern technology and manufacturing processes, contributing to efficient thermal management and the overall performance and longevity of various systems and devices.

| Extrusion Line: | 12 extrusion lines and monthly output can reach 5000 tons. | |

| Production Line: | 5 production line for CNC | |

| Product Capacity: | Anodizing Electrophoresis monthly output is 2000 tons. | |

| Powder Coating monthly output is 2000 tons. | ||

| Wood Grain monthly output is 1000 tons. | ||

| Alloy: | 6063/6061/6005/6060/7005. (Special alloy could be made upon your requirements.) | |

| Temper : | T3-T8 | |

| Standard: | China GB high precision standard. | |

| Thickness: | Based on your requirements. | |

| Length: | 3-6 M or customized length. And we can produce any length you want. | |

| MOQ: | Normally 2 tons. Usually 15-17 tons for 1*20GP and 23-27 tons for 1*40HQ. | |

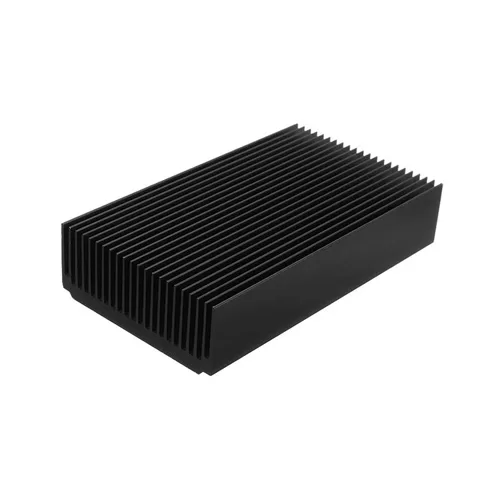

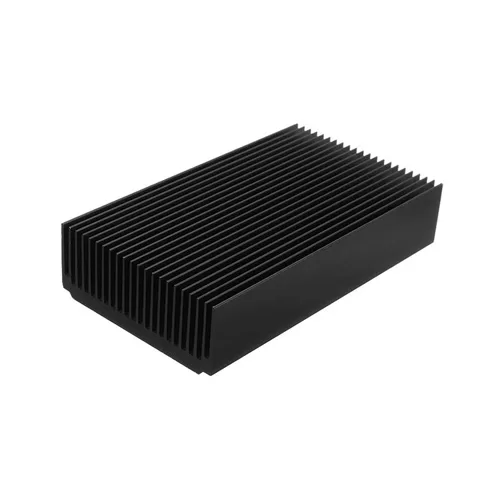

| Surface Finish: | Mill finish, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. | |

| Color We Can Do: | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. | |

| Film Thickness: | Anodized: | Customized. Normal thickness: 8 um-25um. |

| Powder Coating: | Customized. Normal thickness: 60-120 um. | |

| Electrophoresis Complex Film: | Normal thickness: 16 um. | |

| Wood Grain: | Customized. Normal thickness: 60-120 um. | |

| Wood Grain Material: | a). Imported Italian MENPHIS transfer printing paper.

b). High quality China transfer printing paper brand. c). Different prices. |

|

| Chemical Composition & Performance: | Meet and execution by the China GB high precision level. | |

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | |

| Packing: | Plastic film & Kraft paper. Protect film for each piece of profile is also ok if required. | |

| FOB Port: | Foshan,Guangzhou,Shenzhen. | |

| OEM: | Available. | |