Delivery Time: 15-21 days

Service: OEM & ODM

Certification: CE, ROHS, ISO9001

Place Of Origin: Guangdong, China

FOB Port: Foshan, Guangzhou, Shenzhen

Payment Term: T/T, L/C or other payment term can be negociated.

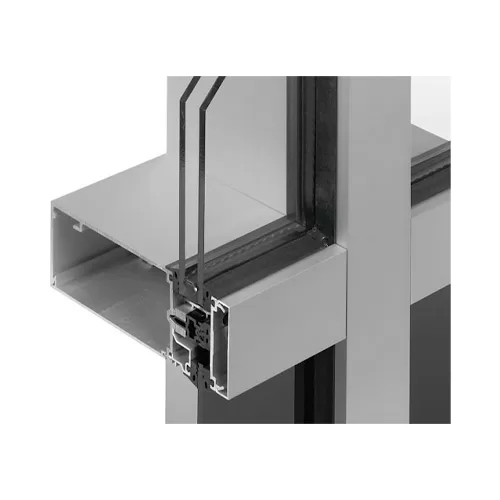

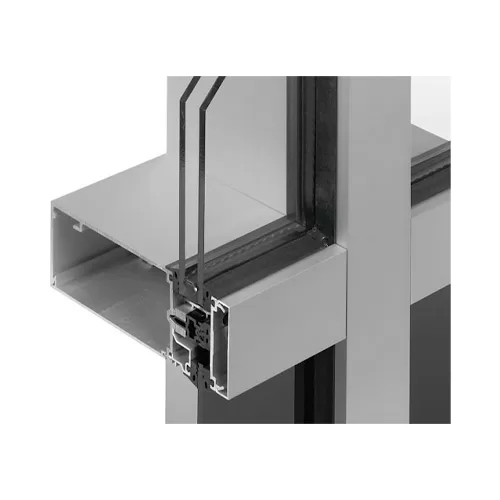

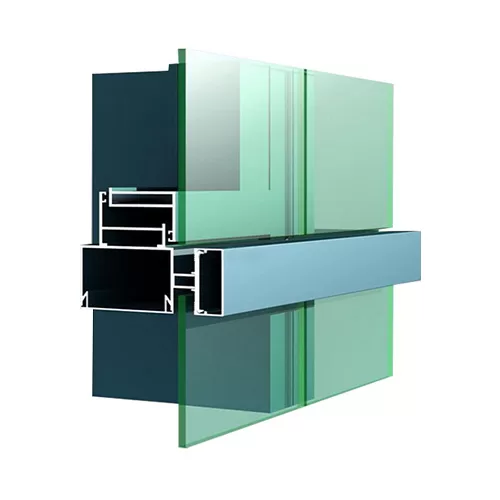

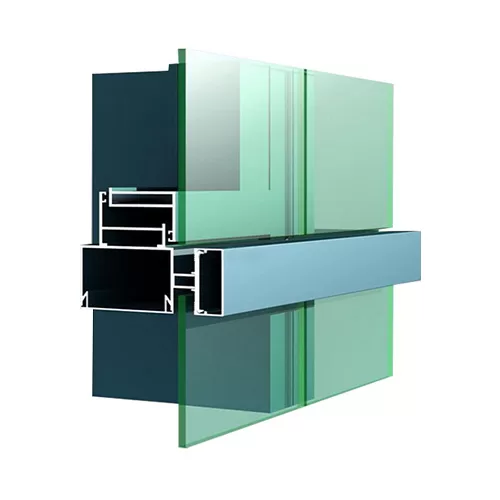

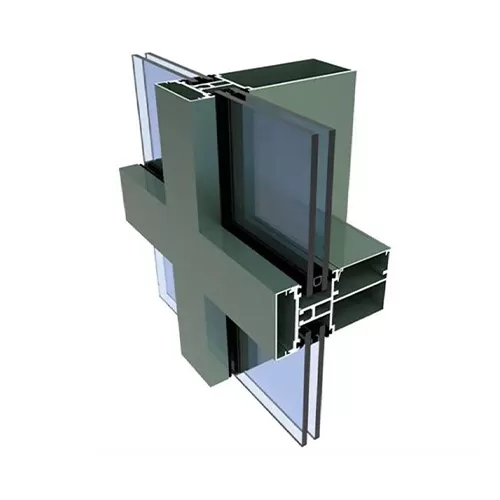

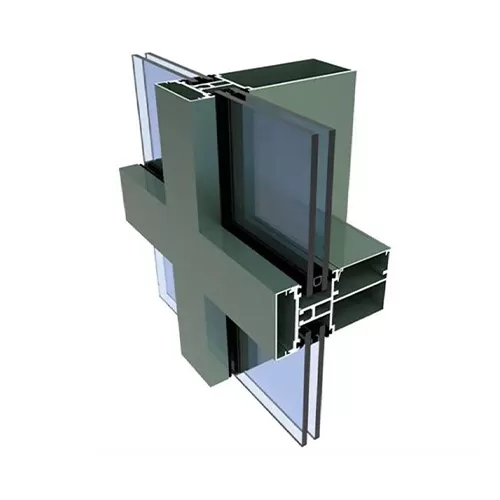

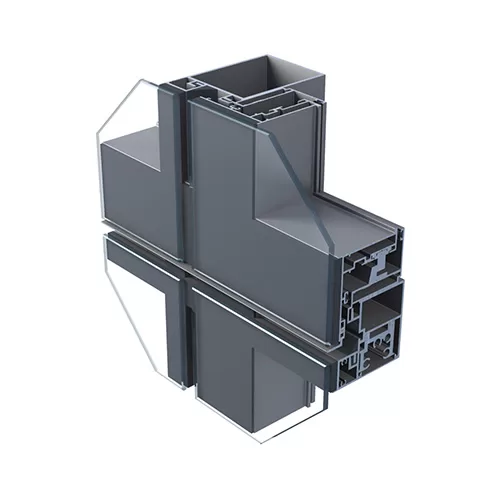

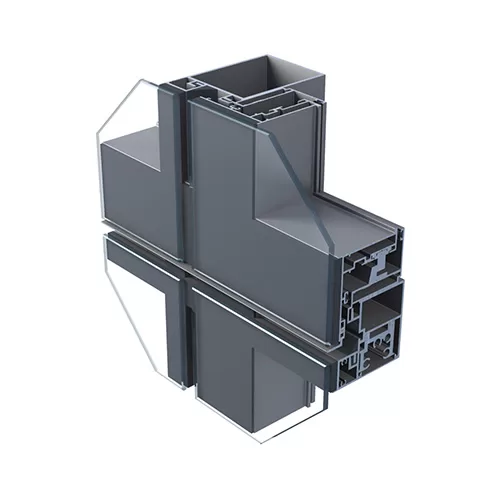

Aluminum curtain wall profiles are essential components in modern architectural designs, offering structural support and aesthetic appeal to buildings with glass facades. These profiles are engineered to provide durability, strength, and versatility while enhancing the overall appearance of the structure.

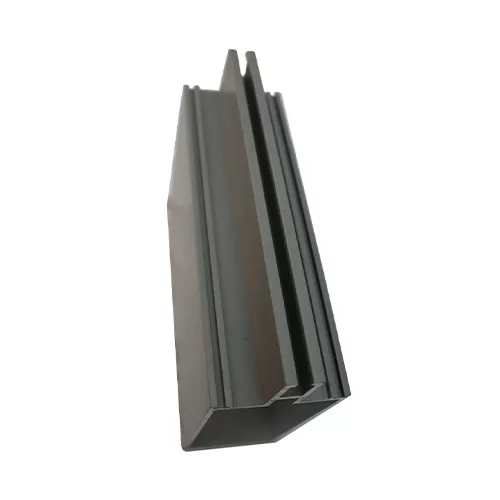

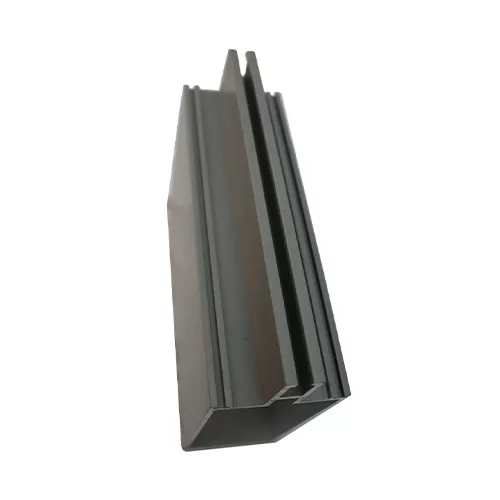

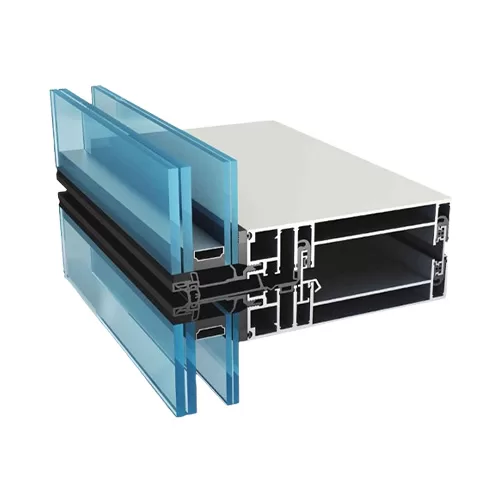

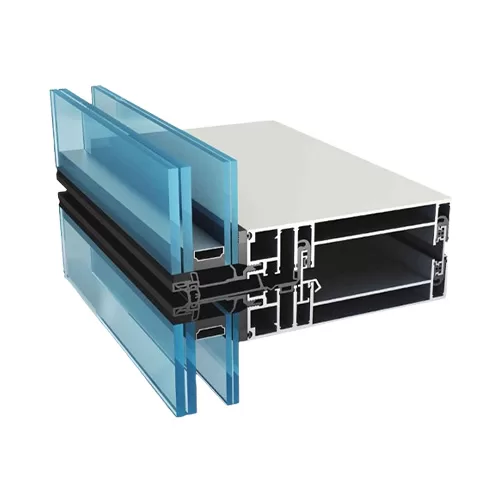

Aluminum curtain wall profiles are designed to accommodate various types of glass panels, including monolithic, laminated, and insulated glass, allowing architects to achieve different aesthetic and performance requirements. The profiles are available in a wide range of shapes, sizes, and finishes to suit different architectural styles and design preferences.

One of the key advantages of aluminum curtain wall profiles is their lightweight yet durable construction, which makes them ideal for large-scale building projects. The use of aluminum ensures corrosion resistance, allowing the curtain walls to withstand harsh weather conditions and maintain their appearance over time.

Moreover, aluminum curtain wall profiles offer excellent thermal performance, helping to improve the energy efficiency of buildings by reducing heat loss and enhancing insulation. This can lead to lower heating and cooling costs for building owners while creating a comfortable indoor environment for occupants.

In addition to their functional benefits, aluminum curtain wall profiles contribute to the aesthetic appeal of buildings, providing clean lines, sleek finishes, and contemporary designs. The versatility of aluminum allows for the creation of intricate patterns, custom shapes, and innovative architectural features, enabling architects to realize their creative vision.

Overall, aluminum curtain wall profiles are essential components in modern building construction, offering a combination of strength, durability, and design flexibility to create stunning glass facades that enhance the visual impact and performance of buildings.

In modern architecture, aluminum curtain wall systems are pivotal elements of building design, seamlessly blending functionality with aesthetics. These systems are meticulously integrated into the architectural framework to create striking façades that define contemporary urban landscapes.

Installation of aluminum curtain wall systems involves a comprehensive process. Architects and engineers collaborate closely to design structures that meet structural, energy efficiency, and design requirements. Fabrication follows, with aluminum profiles and glass panels crafted to precise specifications. During installation, prefabricated units are carefully positioned and secured to the building’s structural frame, with meticulous attention paid to sealing and weatherproofing to ensure durability and performance.

The integration of curtain wall systems with other building components, such as HVAC and electrical systems, is critical to seamless functionality. Finishing touches, including decorative cladding and architectural features, add to the overall aesthetic impact, enhancing the building’s visual appeal.

Altogether, the installation of aluminum curtain wall systems is a sophisticated endeavor that demands precision, expertise, and creativity. The result is an architectural masterpiece that not only meets functional requirements but also elevates the aesthetic and identity of modern buildings.

| Extrusion Line: | 12 extrusion lines and monthly output can reach 5000 tons. | |

| Production Line: | 5 production line for CNC | |

| Product Capacity: | Anodizing Electrophoresis monthly output is 2000 tons. | |

| Powder Coating monthly output is 2000 tons. | ||

| Wood Grain monthly output is 1000 tons. | ||

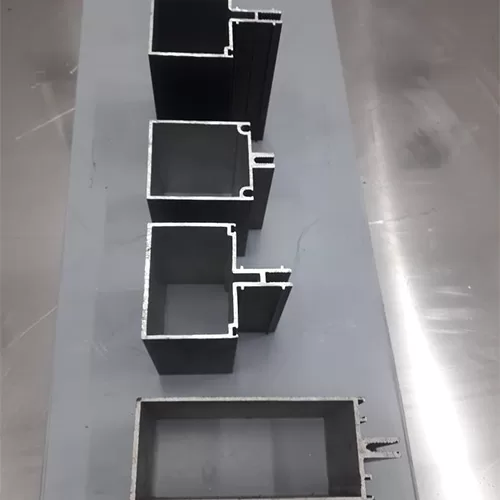

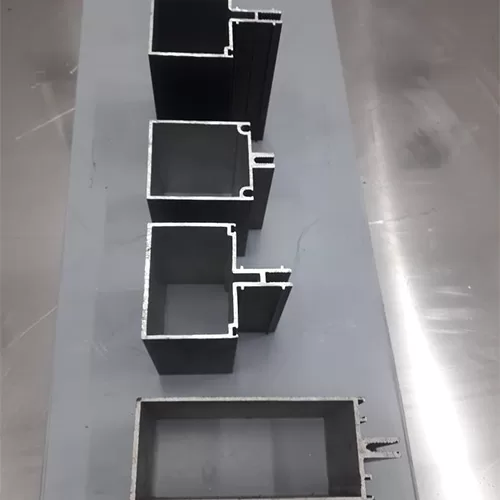

| Alloy: | 6063/6061/6005/6060/7005. (Special alloy could be made upon your requirements.) | |

| Temper : | T3-T8 | |

| Standard: | China GB high precision standard. | |

| Thickness: | Based on your requirements. | |

| Length: | 3-6 M or customized length. And we can produce any length you want. | |

| MOQ: | Normally 2 tons. Usually 15-17 tons for 1*20GP and 23-27 tons for 1*40HQ. | |

| Surface Finish: | Mill finish, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. | |

| Color We Can Do: | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. | |

| Film Thickness: | Anodized: | Customized. Normal thickness: 8 um-25um. |

| Powder Coating: | Customized. Normal thickness: 60-120 um. | |

| Electrophoresis Complex Film: | Normal thickness: 16 um. | |

| Wood Grain: | Customized. Normal thickness: 60-120 um. | |

| Wood Grain Material: | a). Imported Italian MENPHIS transfer printing paper.

b). High quality China transfer printing paper brand. c). Different prices. |

|

| Chemical Composition & Performance: | Meet and execution by the China GB high precision level. | |

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | |

| Packing: | Plastic film & Kraft paper. Protect film for each piece of profile is also ok if required. | |

| FOB Port: | Foshan,Guangzhou,Shenzhen. | |

| OEM: | Available. | |